Class of 2021

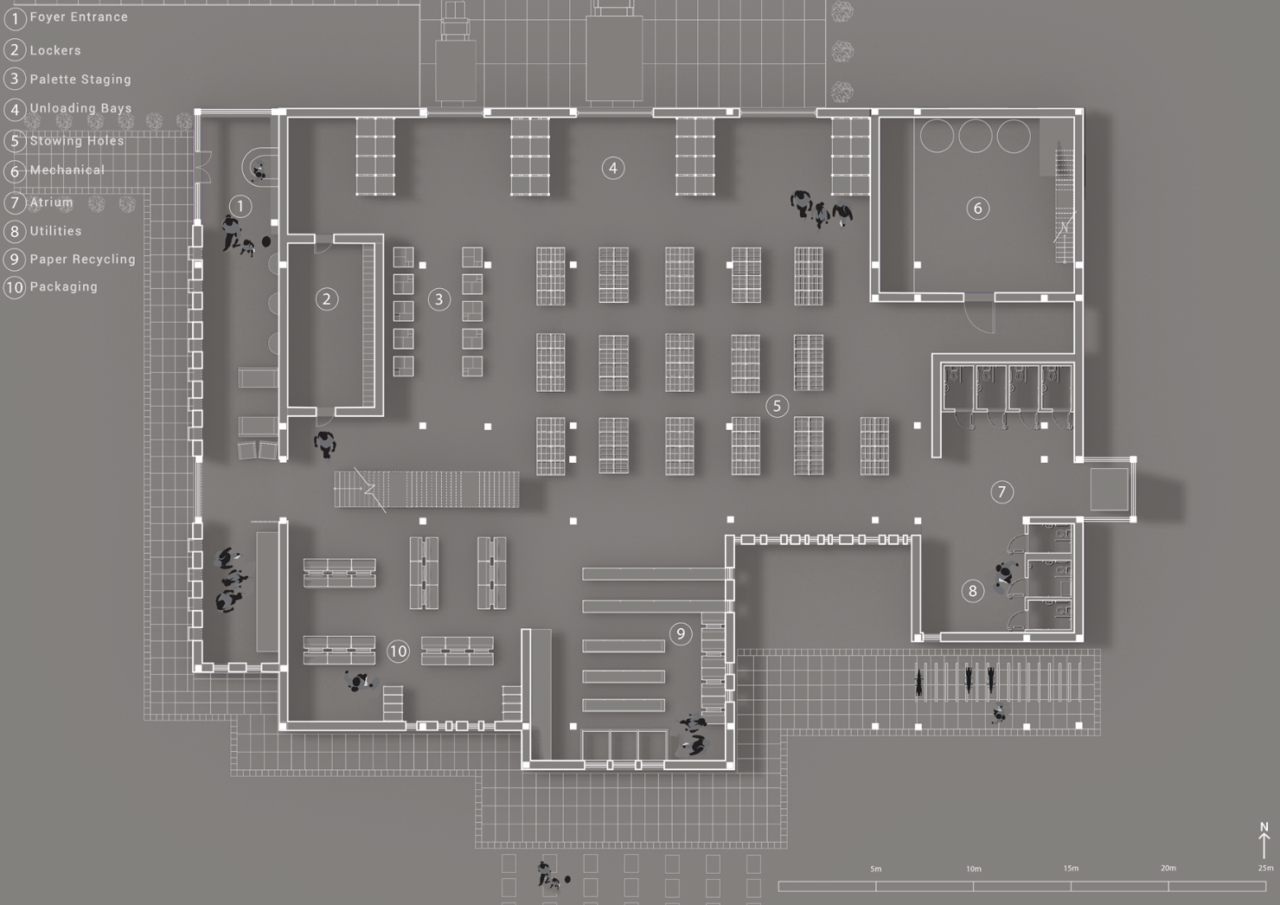

Ground Floor Plan -

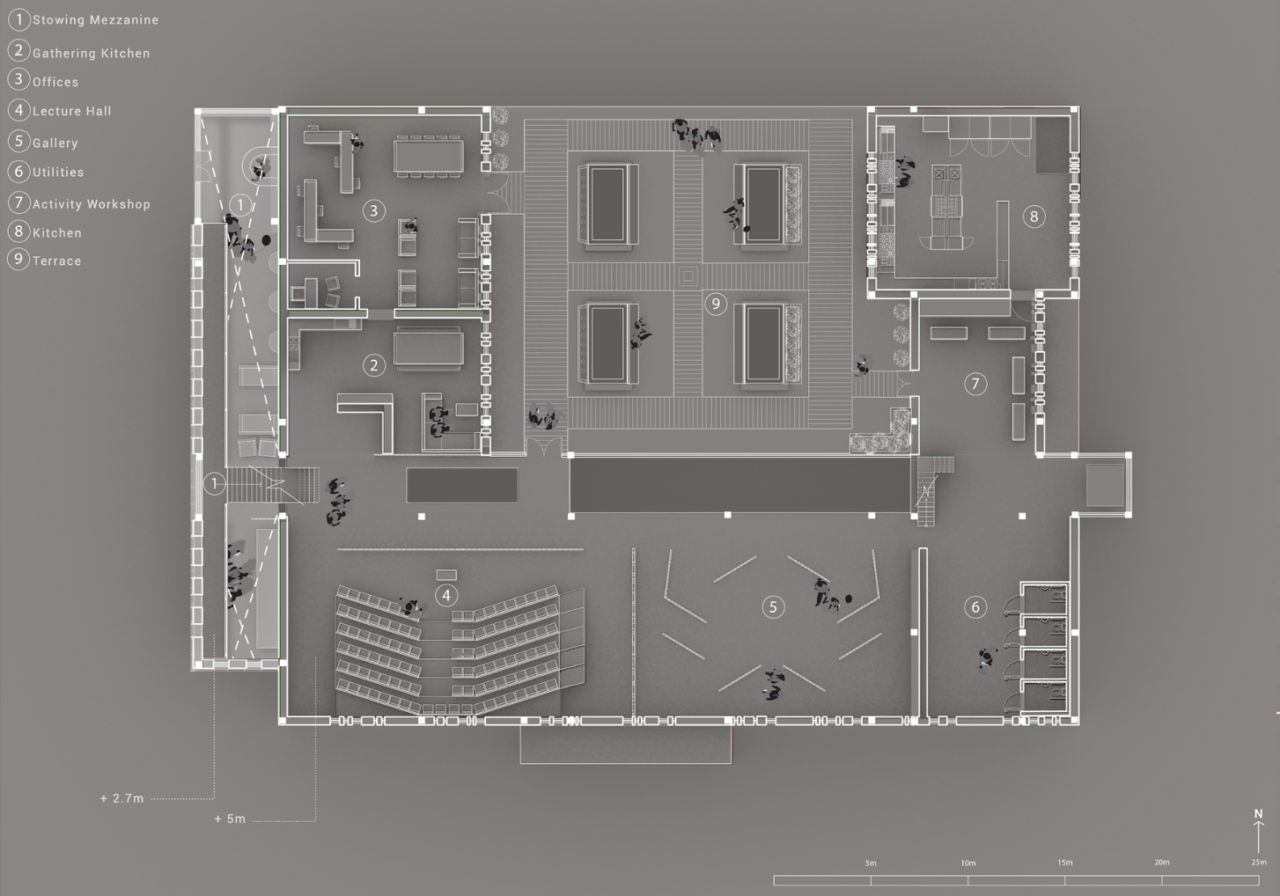

First Floor Plan -

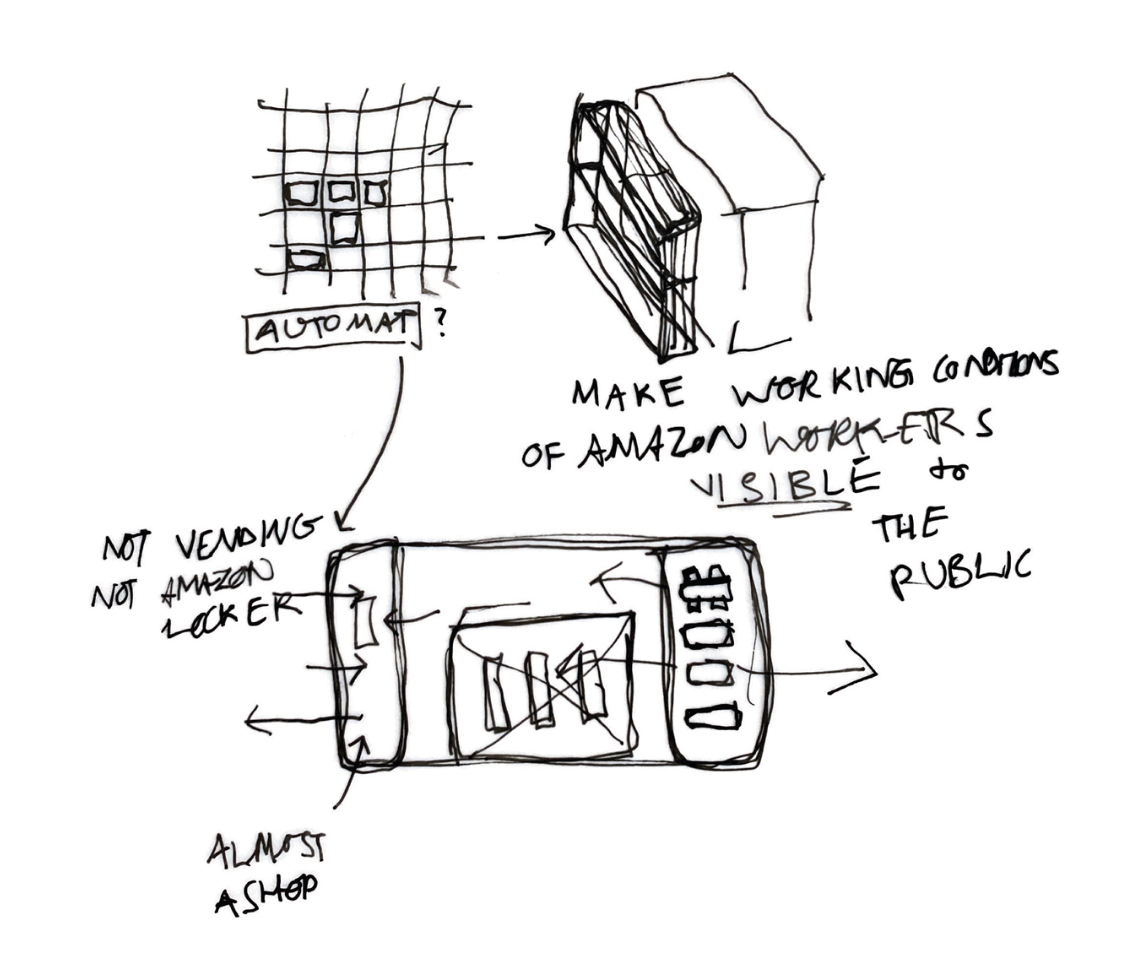

Concept Work -

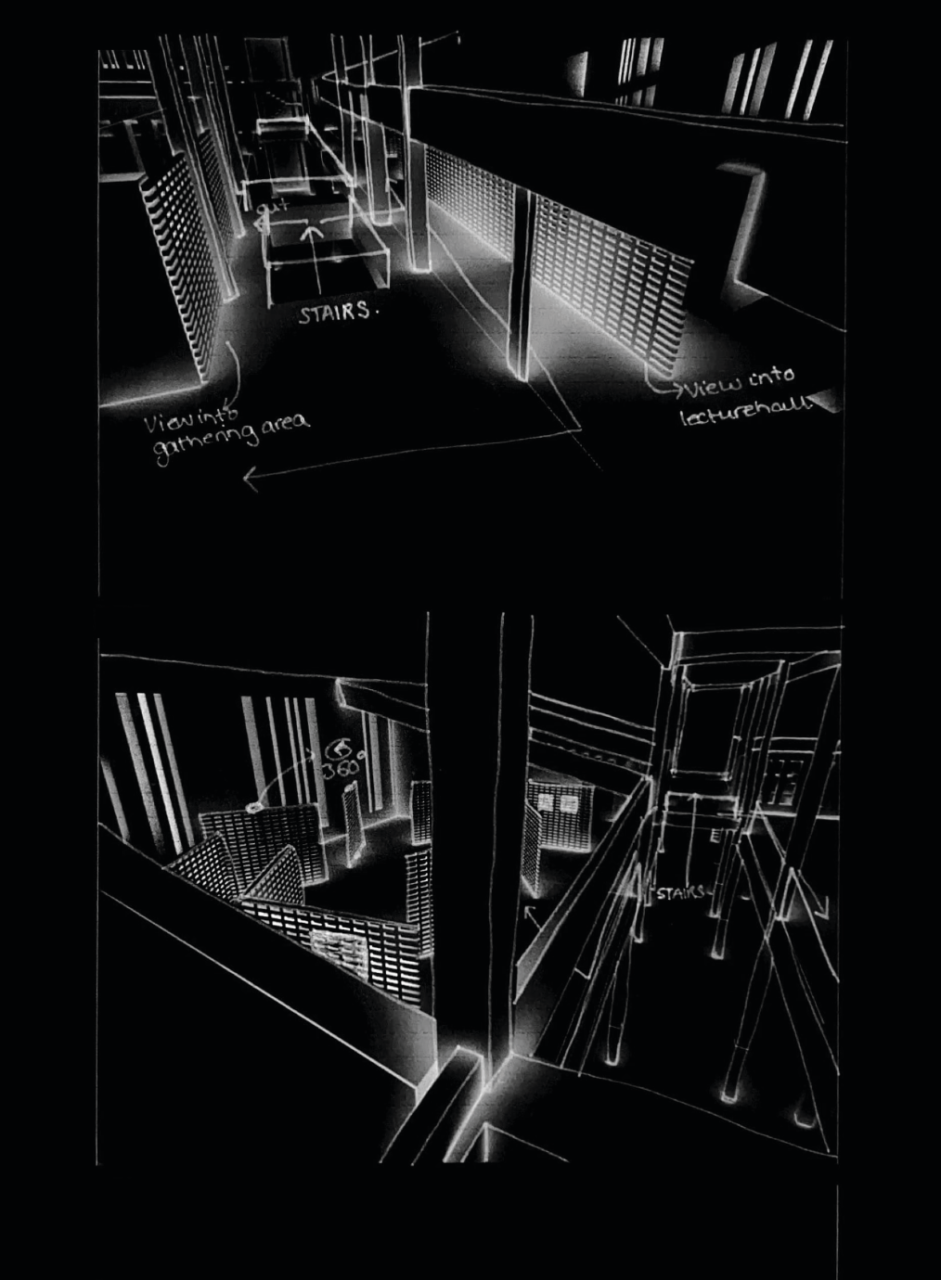

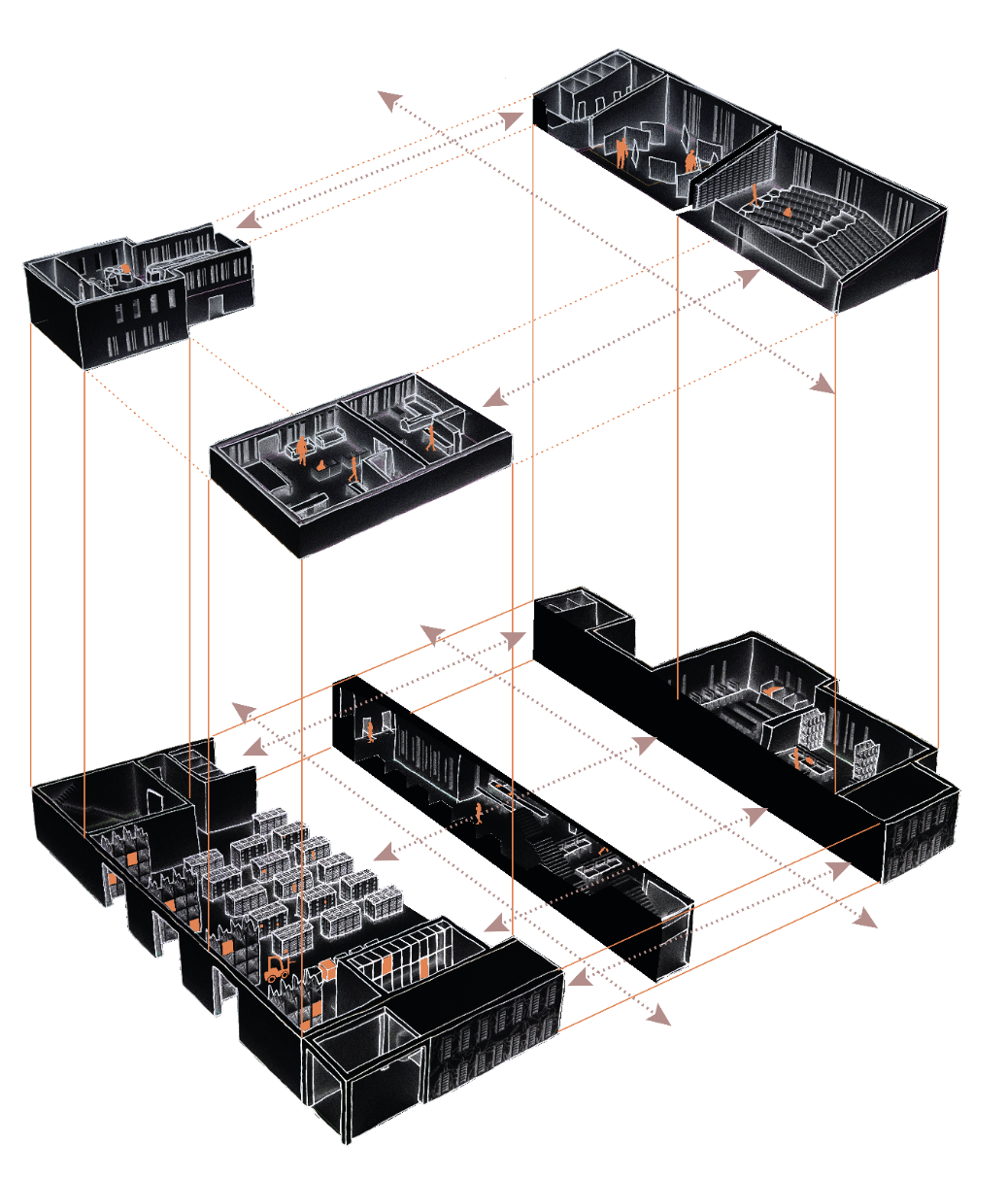

Circulation Concept -

The Atrium as a Connection -

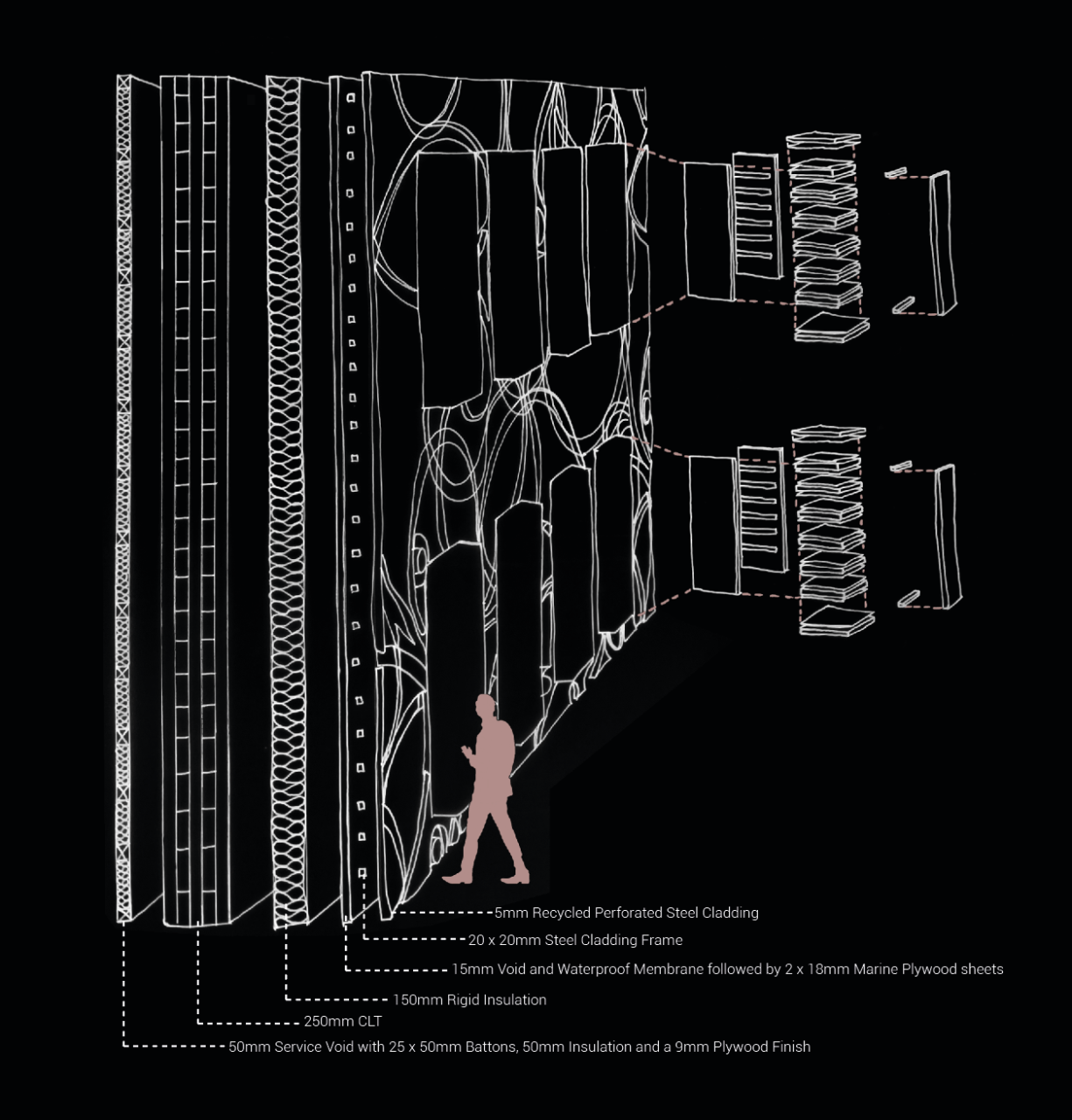

Facade Detail - Stowing Holes

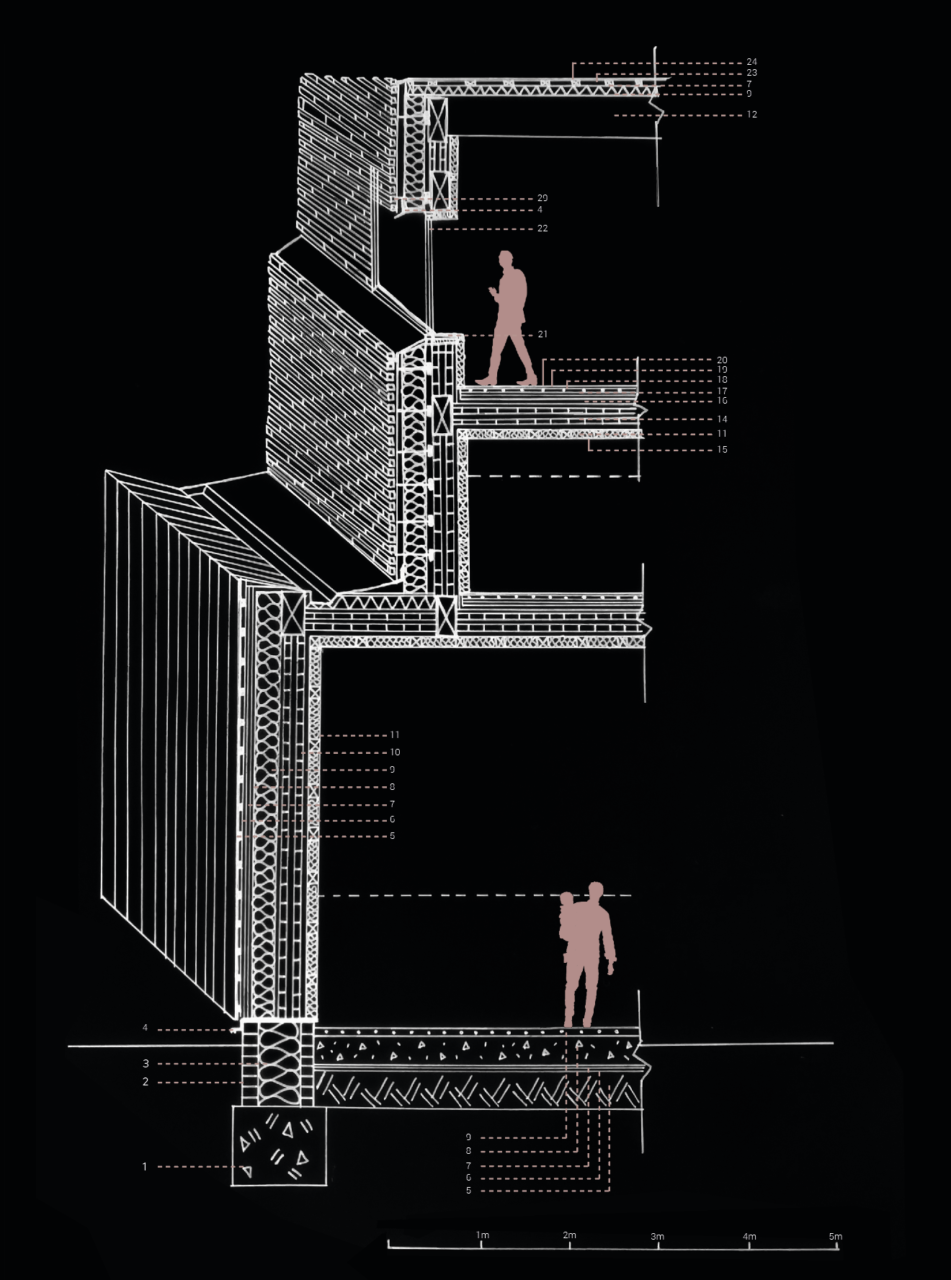

Wall Section -

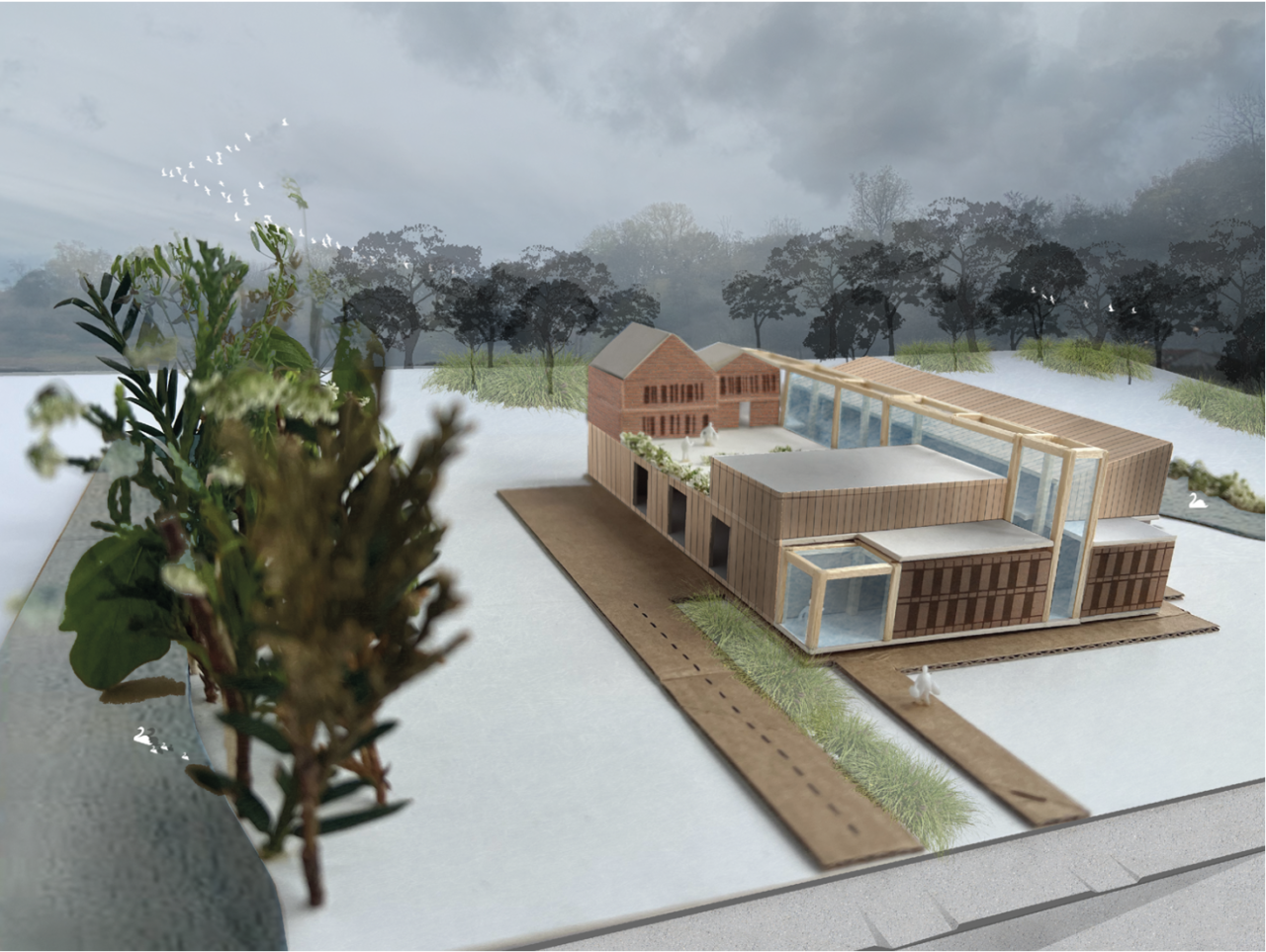

1:200 Model -

Exterior Perspective -

Sectional Perspective -

1

/ 10

Similar Profiles

Class of 2021

Tia palmer

Architecture and Design

Class of 2021

Daniel Shaw

Architecture and Design

Class of 2021